REGA PLANAR 10

BEST PRICE ONLINE

GARANZIA UFFICIALE

GARANZIA UFFICIALEAssistenza italiana

TRASPORTO TRACCIATO

TRASPORTO TRACCIATOSpedizione monitorata

ASSISTENZA DIRETTA

ASSISTENZA DIRETTAConsulenza e preventivi

The new Planar 10 is not simply the evolution of the previous model ... Planar 10 is inspired by the reference REGA turntable, NAIAD, built in very few units in 2013 to celebrate REGA's 40th anniversary (cost about € 42,000). For the Planar 10 Rega used the most advanced materials and solutions starting with an extremely light ceramic platter and materials that reduce mass and improve the rigidity of the entire turntable. The arm mounted on the Planar 10 is also completely new: RB 3000.

(To get the best out of the Planar 10 REGA recommends using the new APHETA 3 head)

ULTRALIGHT BASE

The Planar 10 is Rega's third turntable built using the brand new Tancast 8 ultra-light polyurethane foam material (developed for the aerospace industry). This material is sandwiched between two layers of HPL (high pressure laminate). The HPL is extraordinarily thin and extremely rigid. The new construction allows for a base that is 30% lighter than the original RP8, while offering greater rigidity.

DB TECHNOLOGY (DOUBLE PILLAR TECHNOLOGY) "THE MASS ABSORBES ENERGY - LOST ENERGY = LOST MUSIC"!

A lightweight base coupled with a phenolic resin double ferrule mounted specifically where greater rigidity is required (between the arm mounting point and the platter hub) forms a tension band sound structure. This design prevents the absorption of energy and unwanted resonances that would add unnatural distortion to the music. Likewise, a heavier mass can transfer more unwanted resonances such as motor or hub noise directly onto the rotating disc. The use of the ferrule instead of a compact surface allows the use of the double layer of phenolic resin in the critical areas, allowing at the same time a reduction in the weight of the base, so as to directly solve the problems related to the absorption of the mass and the unwanted transfer of energy.

THE NEW RB3000 ARM

REGA is known for the quality of the bearings of its arms, in particular the meticulous construction of the housing and the pin. Technical characteristics such as "sphericity" and "parallelism" are critical. Over the past three years, REGA has identified a new manufacturing process that improves all of these characteristics while ensuring a construction accurate to the micron. The RB3000 is the first Rega arm to benefit from these improvements. The entire structure of the arm is designed to have the minimum of mechanical joints, using the most rigid materials in critical areas. The tolerances of the RB3000 arm are so tight that no adhesive is used at any point throughout production. Our latest low mass, ultra high precision vertical bearing has been built to fit seamlessly into the Planar 10 turntable philosophy. The RB3000 tonearm utilizes our state-of-the-art vertical bearing with tolerance of less than a thousandth of a millimeter. This guarantees absolutely free movement and no interference. Simply stated, a bearing without friction and without interference is able to read displacements down to the micron within the groove of the disc. The RB3000 also uses the recent, award-winning aluminum tube, individually and meticulously polished, to minimize mass, which has been designed to redistribute mass and further reduce tension and resonance. The advanced tube design increases the rigidity of the whole arm in order to further reduce the stresses on the bearing.

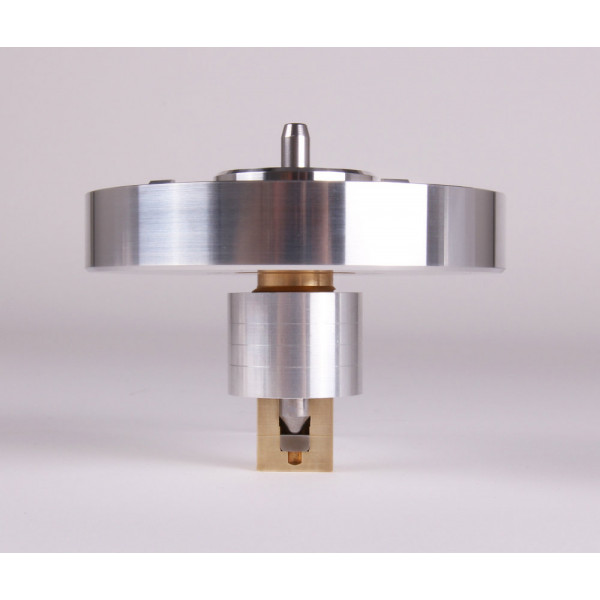

HUB ASSEMBLY

The Planar 10 uses a new low mass center hub assembly. An aluminum plate in a single turned piece and a hardened steel shaft for tools rotate within a bronze housing mounted inside the base. This new mount is designed to eradicate any potential energy transfer or storage in the base.

CERAMIC PLATE

The Planar 10 uses a custom ceramic plate with a flywheel effect. The plate is produced with ceramic oxide powder which is compressed and then fired and finished with diamond so as to ensure perfect accuracy and flatness over the entire surface. It also includes a new type of improved coupling with the counterplate.

24 VOLT LOW NOISE MOTOR

The Planar 10 uses the latest generation of low noise 24 V synchronous motor technology. Assembled in a specific way using the highest level of coupling while maintaining, at the same time, the very high vibration isolation of the previous models. This new mounting technology (from below) is borrowed directly from the reference Rega Naiad turntable. This unique mounting mode eliminates all stress on the motor body: reduced vibrations and stiffer mounting allow for greater guidance thanks to the new EBLT belts. Each motor is individually calibrated by hand to mate with the new PL10 PSU power supply before being installed on the turntable to optimize the anti-vibration circuit.

EBLT BELTS

For three years, Rega has researched and developed with the collaboration of chemists the use of a new rubber compound tailored to its belts. Using a special hardening system, the new belt offers a better constancy of the modulus (constant which represents the degree of a specific property of a substance, specifically elasticity). These new belts are produced by a reference machine designed by Rega which allows the production of perfectly round belts with the exact dimensions, critical characteristics for a perfect stability of the speed.

PL10 PSU

The PL10 PSU offers the ultimate in motor control stability, very simple electronic speed selection and fine adjustment by the user to ensure maximum precision and control for the entire life of the motor. Mounted inside the latest Rega chassis, the PL10 PSU is designed to drive our low noise 24V motor as accurately and quietly as possible. Motor speed and control are achieved by using a new DSP (Digital Signal Processor) generator built around a highly stable crystal. This component divides the crystal's accurate square waves at the exact frequency required to rotate the plate at the required speed. The DSP also generates a practically perfect sine wave to power the engine. Width 420 mm Depth 315 mm Height 125 mm Weight 4.7 Kg

Dimensions: P10 PSU Width 218 mm Depth 320 mm Height 80 mm Weight 3 Kg

SCRIVI MAIL

SCRIVI MAIL